Although some may consider IGBT as "conventional" technology, it still plays a significant role in high-power applications.

Today, most news and discussions in the semiconductor industry revolve around devices based on new wide-bandgap (WBG) materials such as silicon carbide (SiC) and gallium nitride (GaN). However, just a few years ago, the preferred solution for many applications was the Insulated Gate Bipolar Transistor (IGBT).

There is still a presence of medium to high-power applications that utilize IGBTs, and the devices themselves continue to evolve. In this article, we will delve into the details of IGBTs and explore their existing and emerging applications.

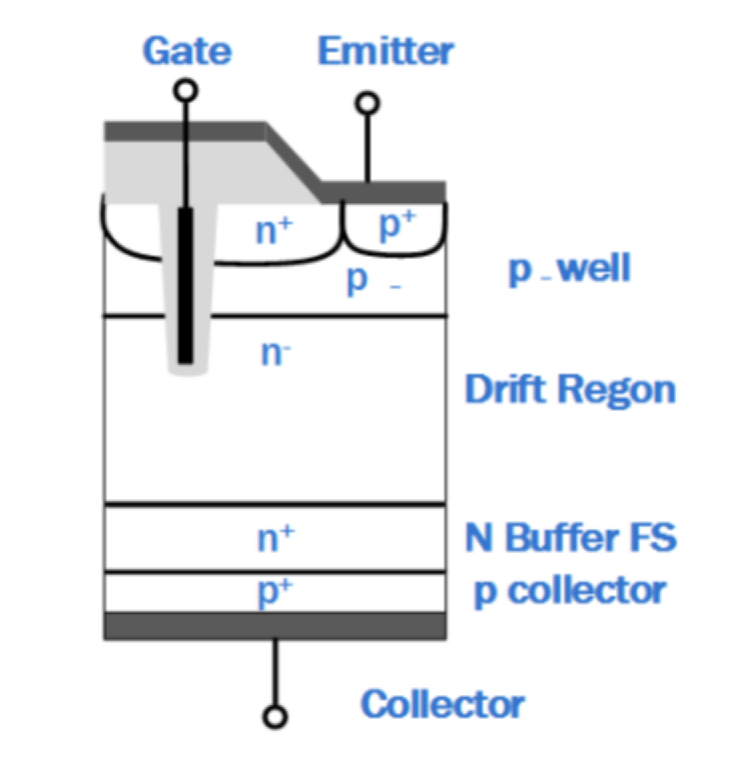

IGBT: Physical Structure

IGBT is a semiconductor transistor or switch composed of four alternating layers of semiconductor materials (PNPN). When the correct voltage is applied to the device's gate, it allows current to flow—this conduction stops when the voltage is removed.

Since its inception, IGBT has undergone continuous refinement and improvement, particularly in reducing switching losses and creating thinner structures. Nowadays, IGBTs commonly incorporate a trench gate combined with a field stop structure as a means to suppress parasitic NPN characteristics within the device. Once achieved, conduction losses and saturation voltage are reduced, resulting in benefits such as increased power density.

Figure 1: Structure of Field-Stop IGBT with Trench Channel Cutoff

IGBT Utilization and Technical Examples

IGBT finds wide applications in various fields, including solar inverters, energy storage systems, uninterruptible power supplies (UPS), motor drives, electric vehicle chargers, industrial welding, and household appliances. Typically, the topology structure is chosen specifically to meet the requirements of a particular application. Let's compare and contrast some popular applications.

Industrial Welding

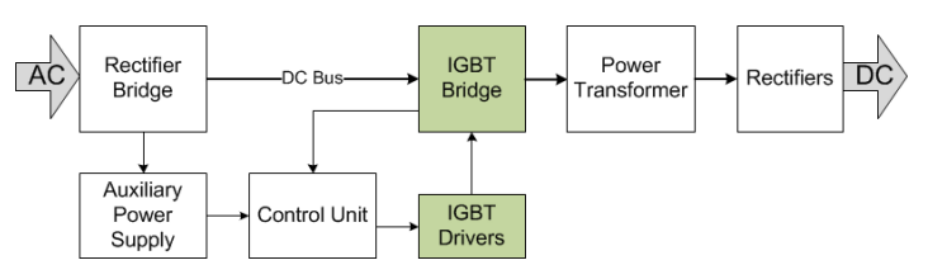

Considering the demand for higher-quality welding, it requires precise control over the welding process. Therefore, inverters are commonly used instead of typical welding transformers because DC output current can achieve the necessary accuracy.

There is also a safety aspect since DC current is generally considered safer. From the user's perspective, inverters are smaller and lighter compared to transformers, making welding machines more portable and convenient to use.

In a typical welding machine, single-phase or three-phase AC power is rectified to form the DC bus voltage. The rectifier also powers the small converters that generate the voltage required by the control unit. The DC bus voltage powers the inverter, which typically has a nominal output voltage of around 30 VDC. However, during operation, under open-circuit load conditions, the voltage may double and drop to almost 0V (actually short-circuit) when triggering the welding arc."

Figure 2: Overview of a Typical Welding Machine

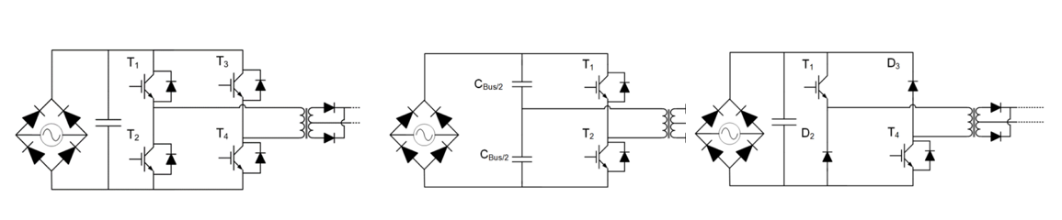

Many different topology structures are suitable for inverter-based welding machines. However, the most common ones include Full Bridge (FB), Half Bridge (HB), and Two-Switch Forward. In FB and HB topologies, the switching frequency is typically in the range of tens of kHz, usually around 20 - 50 kHz. The duty cycle is controlled based on the load level and output voltage. In terms of control schemes, it is often constant current.

Figure 3: Common topologies include FB, HB, and Two-Switch Forward

Industrial Motor Drivers

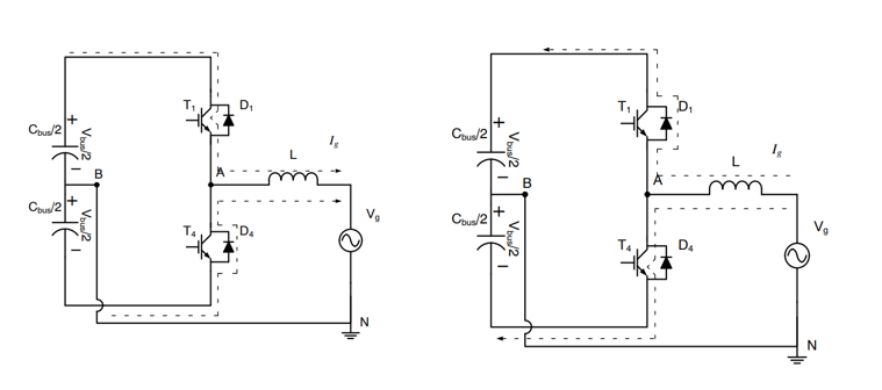

One of the most common industrial applications is industrial motor drivers, which can be used for robots, large machinery, or many other motion-dependent applications. Most motor driver applications are configured as HB, with frequencies between 2 kHz and 15 kHz. The resulting output voltage depends on the switch status and current polarity.

Figure 4: Half Bridge Topology displaying positive and negative output current.

The motor is an inductive load, so the current increases rapidly. When positive current flows (Ig > 0), the high-side transistor (T1) turns on and delivers energy to the load (Vg). However, if the load current Ig flows in the opposite direction (negative polarity), the current flows back through D1, returning the energy to the DC source.

If the low-side transistor conducts (T4 is on) and the high-side transistor (T1) is off, a voltage equal to half of Vbus (-Vbus/2) is applied to the load, reducing the current. If Ig is greater than zero, the current flows through D4, returning the energy to the bus source.

Modern Induction Cooktops

Induction cooking has replaced traditional heating by transferring heat energy to the bottom of a pan/pot through electric heating elements. It operates based on the principle of induced currents circulating within the bottom of the pot. For induction cooktops to function properly, the pot's bottom must be physically close to the coil, and only certain metals are suitable - those with high magnetic permeability.

The principle is similar to common power transformers, with the coil as the primary and the pot's bottom as the secondary. It shares many similarities with modern induction charging technology as well.

The heat required for heating the pot comes from the eddy currents circulating in the bottom layer or, more specifically, from the resistance offered by these current flows. Through inductive coupling, approximately 90% of the energy is transferred to generate heat in the pot. A typical smooth glass-top stove can only transmit about 70% of the energy, resulting in a threefold reduction in losses.

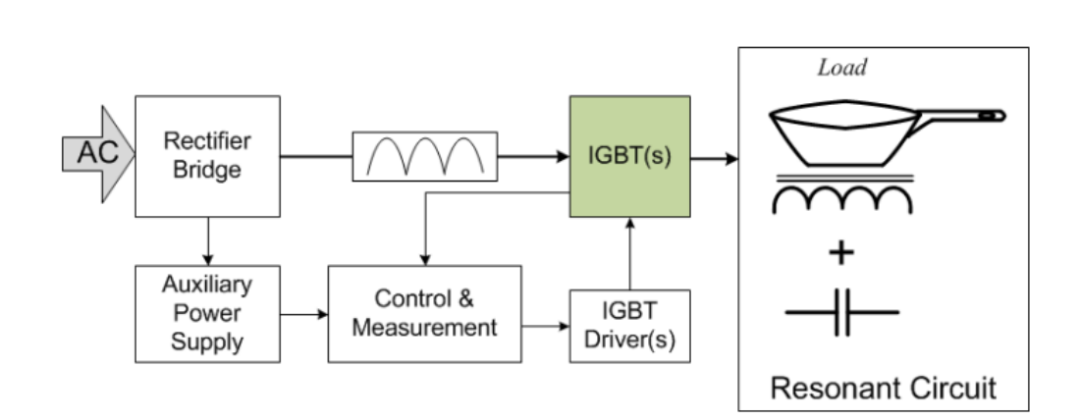

The topology used is not significantly different from a welding circuit. The main AC power is rectified and drives a small auxiliary power supply for the inverter and controller. The inverter induces the current into copper coils, creating an electromagnetic field that induces eddy currents in the pot. The generated heat is equal to the resistance of the pot's bottom multiplied by the square of the induced current - known as the "Joule effect

Figure 5: Overview of a Typical Induction Cooktop Circuit

Unlike welding machines, the control scheme for induction cooktops is typically a frequency variation scheme. While this is a simple method, the challenge lies in controlling the required frequency range for output power over a wide range.

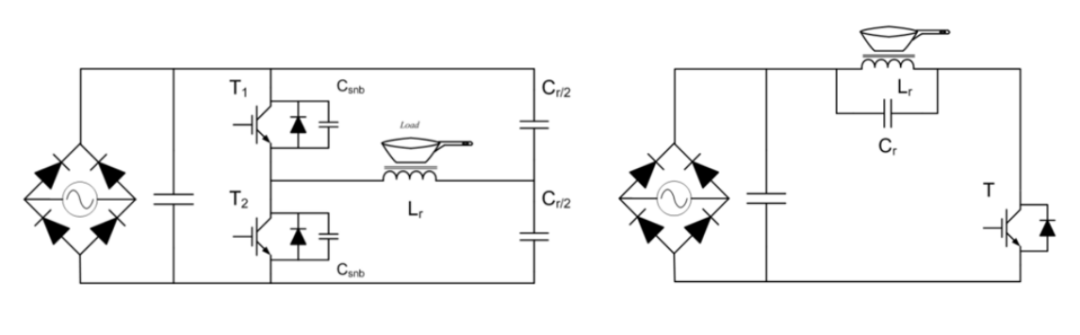

Even at the high frequencies required for induction cooktops, resonant converter circuits can operate with high efficiency. Therefore, resonant circuit converters are commonly used for this application, especially resonant half-bridge (RHB) converters and quasi-resonant (QR) inverters. RHB converters are particularly favored due to their ability to handle a wide range of loads. Advanced control techniques such as zero-current switching (ZCS) or zero-voltage switching (ZVS) are typically employed to keep power losses to a minimum.

Figure 6: Typical Examples of RHB and QR Topologies

Due to the cost-effectiveness of this topology, QR converters are often used in low-power (below 2W peak power) induction cooktop applications.

Solar inverters and UPS

When using the half-bridge topology in applications that require fast switching, there are many challenges, including:

- Only two output voltages can be achieved

- Switching losses can be significant

- Driving the large gates can be challenging

- Component stress affects reliability

- Increased ripple current and EMI require extensive filtering

- Incompatible with high-voltage DC bus

- Thermal design is not trivial

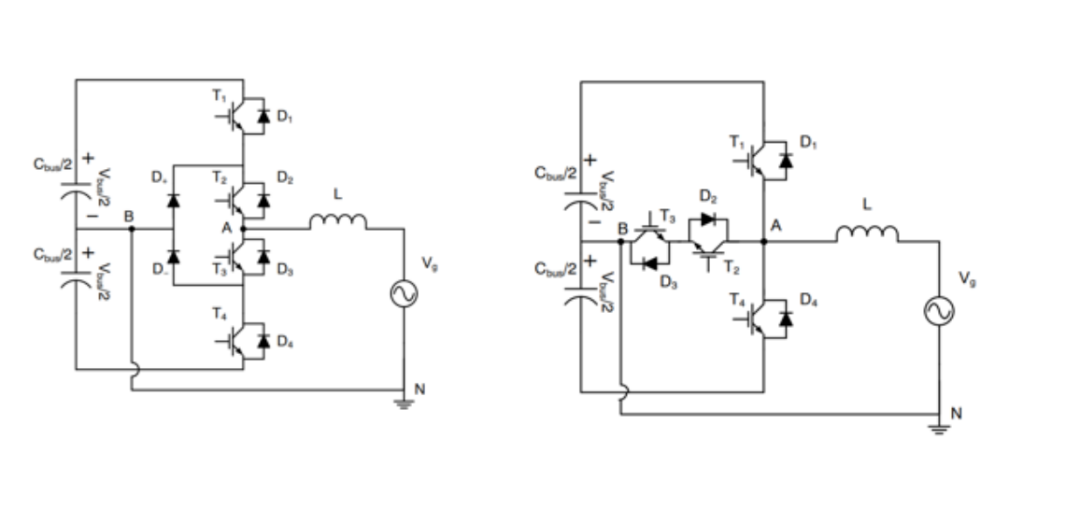

In modern applications, the HB topology is being replaced by critical applications such as Uninterruptible Power Supplies (UPS) and solar photovoltaic (PV) inverters. Three-level topologies are becoming dominant, known as I-Type and T-Type.

There are many aspects that need improvement, including reducing the voltage across the active devices to lower losses, reduce harmonic distortion, and allow for the use of smaller components. Most importantly, these topologies can significantly reduce switching losses, achieving efficiency up to 98% when switching at high frequencies ranging from 16 kHz to 40 kHz.

Figure 7: I-Type and T-Type Converter Topologies have many advantages compared to HB

Looking to the Future

Although some may view IGBT technology as "traditional," it still plays an important role in high-power (high voltage/current) applications. IGBT technology continues to evolve, with Vcesat values approaching 1V, and structural improvements increasing density and reducing losses.

As always, when using IGBTs, designers must have a full understanding of their application requirements and select appropriate topologies to ensure optimal results and performance.

Comments

Post a Comment